Monitoring a Massive Mac hamburger’s journey from ranch to fast-food restaurant isn’t simple. Right this moment’s extremely segmented beef provide chain consists of a wide selection of ranches, feedlots, packers, processors, distribution facilities, and eating places, every with its personal set of fastidiously collected knowledge. But in in the present day’s advanced digital world, organizations want extra visibility than ever to handle stock, know the place merchandise are coming from, and preserve client belief, says Bob Carpenter, president and CEO of GS1 US, a not-for-profit, worldwide supply-chain requirements group.

To handle this wealth of knowledge, industries use one of many easiest and most dependable knowledge requirements: the barcode. This ubiquitous machine-readable set of parallel strains encodes distinctive identification numbers for many objects at factors of sale across the globe. Though a Massive Mac isn’t scanned, the journey of its substances is known and communicated utilizing these requirements.

To realize higher visibility into its provide chain, fast-food restaurant large McDonald’s teamed up with provider Golden State Meals in a pilot venture that makes use of radio-frequency identification (RFID) know-how to mechanically monitor contemporary beef’s motion from producer to restaurant in close to real-time. This technique guarantees to “create a golden digital thread of traceability, giving companions throughout our ecosystem the knowledge they should construct belief, enhance transparency, and drive worth,” says Sue Fangmann, U.S. provide chain companies director for McDonald’s.

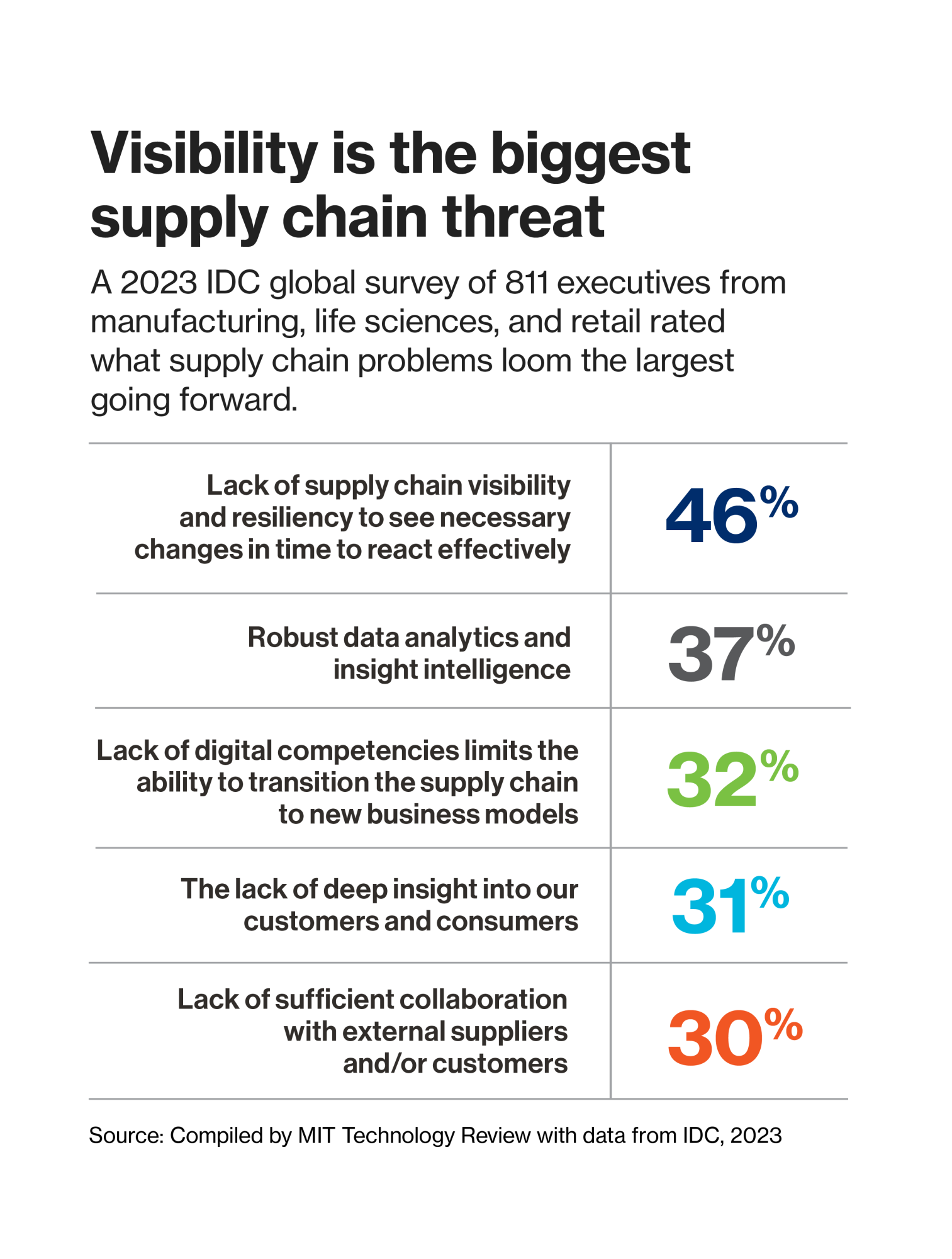

Welcome to the “phygital” universe the place belongings from the bodily and digital worlds are blended to unlock huge volumes of data. In recent times, labor shortages, transportation failures, and political volatility have contributed to extreme provide chain disruptions. Organizations like McDonald’s are discovering phygital instruments can handle these difficulties by merging the effectivity and agility of know-how, together with synthetic intelligence (AI)—with assist from bodily object identifiers—to create quicker, extra correct, extra clear, and extra resilient provide chains.

Obtain the total report.

This content material was produced by Insights, the customized content material arm of MIT Expertise Assessment. It was not written by MIT Expertise Assessment’s editorial employees.