As a toddler, Emily Baker liked to make paper variations of issues: cameras, a spaceship cockpit, buildings for a city in outer area.

It was a behavior that caught. Years later, learning structure in graduate faculty on the Cranbrook Academy of Artwork in Michigan, she was taking part in round with some paper and scissors. It was 2010, and the varsity was about to purchase a CNC plasma cutter, a computer-controlled machine able to reducing strains into sheets of metal. As she thought of how she may experiment with it, she made a putting discovery.

created prototypes by making cuts and folds in sheets of paper earlier than

shifting to digitally reduce metal.

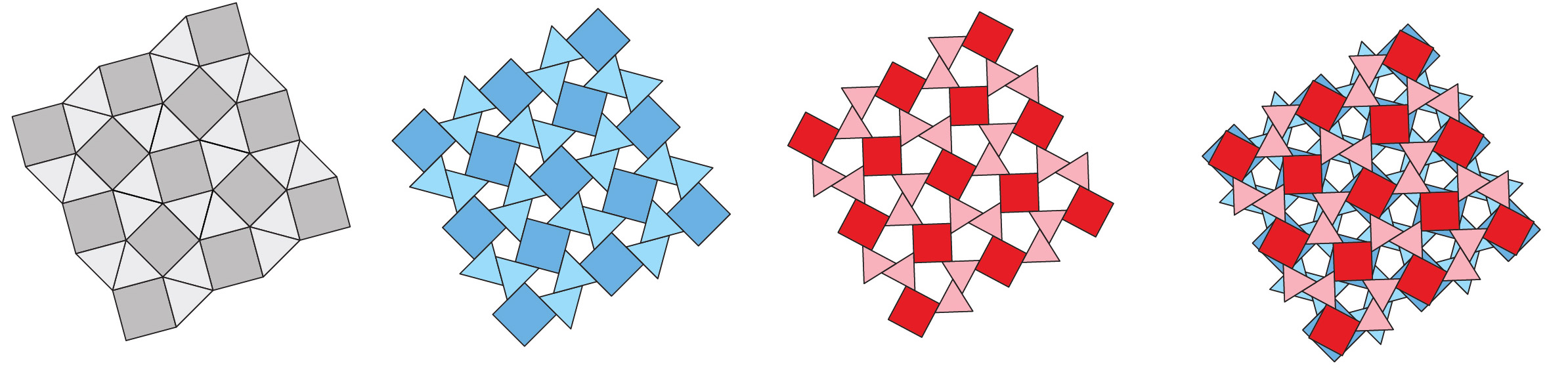

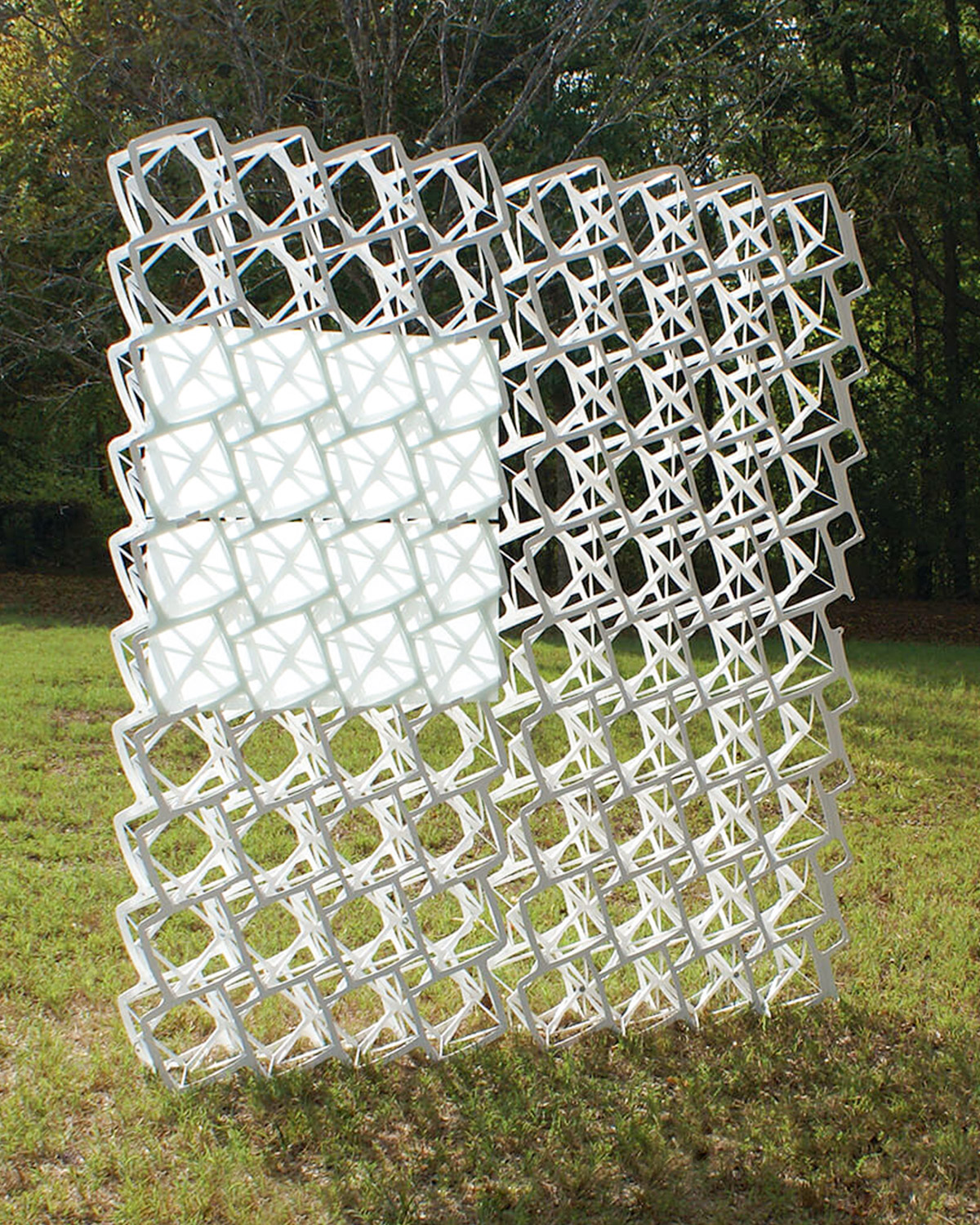

By making a sequence of cuts and folds in a sheet of paper, Baker discovered she may produce two planes related by a posh set of skinny strips. With out the necessity for any adhesive like glue or tape, this sample created a floor that was thick however light-weight. Baker named her creation Spin-Valence. Structural assessments later confirmed that a person tile made this manner, and rendered in metal, can bear greater than a thousand instances its personal weight.

lab on the College of Arkansas.

In chemistry, spin valence is a principle coping with molecular conduct. Baker didn’t know of the present time period when she named her personal invention—“It was a complete accident,” she says. However diagrams associated to chemical spin valence principle, she says, do “appear to have a community of patterns which might be similar to the tilings I’m working with.”

Quickly, Baker started experimenting with linking particular person tiles collectively to provide a bigger airplane. There are maybe hundreds of geometric reducing patterns that may create these multiplane constructions, and he or she has to this point found solely a few of them. Sure patterns are stronger than others, and a few are higher at making curved planes.

Baker makes use of software program to discover every sample sort however continues to work with reduce paper to mannequin prospects. The Type Discovering Lab at Princeton is now testing varied tiles below rigidity and compression masses, and the outcomes have already proved extremely sturdy.

Baker can be exploring methods to make use of Spin-Valence in structure and design. She envisions utilizing the approach to make shelters or bridges which might be simpler to move and assemble following a pure catastrophe, or to create light-weight constructions that could possibly be filled with provides for missions to outer area. (Nearer to residence, her mom has begun passing alongside concepts to her quilting group; the designs bear a robust resemblance to quilt patterns.)

“What I discover most fun in regards to the system is the way in which it provides stiffness to one thing that was beforehand very versatile,” says Isabel Moreira de Oliveira, a PhD candidate in civil engineering at Princeton, who’s writing her dissertation on Spin-Valence and testing which shapes work finest for particular functions. “It totally adjustments the conduct of one thing with out including materials to it.” Plus, she provides, “you possibly can ship this flat. The meeting info is embedded in the way it’s reduce.” This might assist cut back transportation prices and decrease carbon emissions generated from transport.

Baker grew up in Alabama and Arkansas, the daughter of a librarian and a chemical engineer at Eastman Kodak. Everyone within the household made issues by hand—her mom taught her the best way to sew, and her father taught her the best way to work with wooden. In highschool, she took some lessons within the faculty’s agricultural program, together with welding, the place she had a very supportive instructor. “I’ll inform you who the very best two welders within the class are gonna be proper now,” she recollects him saying, as he pointed at her and the one different feminine pupil. And, she says, “it was true. We picked it up a little bit quicker than the fellows. It was actually empowering.”

Baker went on to review chemical engineering on the College of Arkansas in Fayetteville earlier than she switched to structure, drawn to the extra tactile work. After 5 years at a small structure agency in Jackson, Mississippi, she enrolled at Cranbrook, the place she sensed she would have the area and instruments to experiment. She now teaches within the structure program on the College of Arkansas.

Little question her expertise in highschool welding class aided in a more moderen collaboration. Collectively together with her UA colleague Edmund Harriss, an assistant professor of arithmetic and artwork, she has developed Zip-Type—a system for welding and bending two sheets of metal collectively to make advanced 3D curves utilizing low-cost instruments and simply discovered abilities.

As a course of, it’s “a bodily manifestation of integrating differential properties of the curve,” Harriss says. “The way in which the mathematical principle hyperlinks to manufacturing course of in Zip-Type is extremely clear and chic.” He explains that Baker’s willingness to interact critically with the arithmetic units her other than different architects he has labored with: “I feel typically individuals get intimidated by the arithmetic and attempt to fall again on their experience to say the place the arithmetic isn’t working.” Baker wasn’t like that.

Like Spin-Valence, Zip-Type has potential functions in building. Shortly after creating the approach, Baker met Mohamed Ismail, now an assistant professor of structure on the College of Virginia, who was then a PhD pupil at MIT. He was engaged on low-cost, low-carbon structural programs for housing in creating nations. When Ismail discovered that Baker and Harris had discovered a technique to make advanced 3D constructions out of flat sheets, his thoughts instantly went to concrete. A system like this, he says, is “precisely the sort of factor that’s obligatory while you’re making an attempt to construct advanced concrete formwork [molds to pour the concrete into] in locations the place you don’t have a robotic arm or 3D printer.”

In a venture they labored on collectively, Baker and Ismail used Zip-Type to create a mildew for a 16-foot prototype curved beam that’s extra environmentally sustainable than a standard beam, decreasing the overall carbon emissions related to useful resource extraction, manufacturing, transport and different levels within the typical life cycle of a beam by 40%.

Whereas most concrete buildings use vastly extra materials than is structurally obligatory, curved beams save concrete by utilizing materials solely the place it’s wanted to bear a structural load. Concrete is answerable for roughly 8% of complete international carbon emissions, however it is usually desperately wanted to construct housing, particularly in locations like India and Africa, the place the inhabitants is forecast to develop quickly within the subsequent 20 years. Zip-Type calls for extra labor than extra automated processes, however the gear it makes use of is extra inexpensive.

Ismail and Baker at the moment are working with a fabrication firm in Kenya to exhibit to actual property builders and an African housing nonprofit that this expertise is aggressive on value with conventional strategies, and thus has a key function to play in inexpensive building. The development trade within the US could be mind-numbingly sluggish to undertake new strategies, Baker and Ismail each say, however they consider Zip-Type can simply be introduced into constructing tasks, utilizing instruments and supplies which might be already out there.

a system for welding and bending two sheets of metal collectively to make advanced 3D shapes.

Zip-Type has artistic potential, too. Danielle Hatch, an artist identified for large-scale material installations, is utilizing the system to make a public sculpture in Arkansas impressed by the motion of ribbons on the dancers she noticed at a Hispanic cultural competition. “How may I evoke that sense of lightness and play, with metallic?” she puzzled. Zip-Type allowed her to make metal that she describes as “lyrical.”

Baker has been impressed by the work of R. Buckminster Fuller, the polymath identified for popularizing the geodesic dome—and for turning his thoughts to the whole lot from inexpensive housing and transportation to renewable power. She has studied his story carefully, particularly reflecting on the gaps between the broad scope of his thought—which regularly sought to revolutionize complete programs—and the restricted real-world adjustments that resulted from his concepts. “Is there one thing I ought to have discovered from his life and expertise?” she wonders.

Like Fuller, whose work prolonged far past structure to think about the methods individuals relate to at least one one other and to supplies, Baker doesn’t assume nearly bodily varieties however about how individuals construct, stay, and manufacture—and the hierarchies that decide who does what. She thinks of structure as all the time being in dialog with the physique of the builder. A brick, she factors out, is a superb instance as a result of it’s the right dimension for a employee to carry whereas slathering it with mortar. Baker desires the instruments she creates to be simply as sensible.

Sofi Thanhauser is a author, artist, and musician based mostly in Brooklyn, New York, and the writer of Worn: A Individuals’s Historical past of Clothes.